Elipse Software announces new system for ABB’s Masterbus networks

The solution was designed to replace ABB’s original operation stations (Advant OCS – Operator Control Station) such as AS500, whose spare parts are hard to find due to their proprietary, non PC-based hardware; the company was chosen because of Elipse solutions’ great connectivity. Thanks to this, the technology enables data exchange and process interaction with other systems, such as ERPs, PIMS, and Optimization Systems, requiring no production downtime.

Setting up ABB Advant process screens in E3 Studio

The solution features a communication interface (driver) that allows integrating several controllers’ databases to Elipse E3’s real-time database via DCS. With it, operators can read and write properties from any control block, providing a complete graphic application for operating the plant and the main resources originally offered by Advant OCS. Because operators are already used to the system’s current interface, the driver helps ease this transition. It also features support to the network redundancy both in the station and in the controllers, thus allowing data exchange to be distributed freely according to the available network path.

PIDCON’s Faceplate and MB300 driver settings

About ABB Advant OCS system

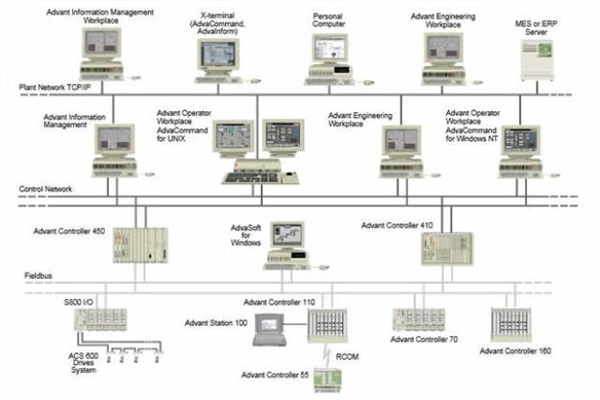

The ABB Advant system was developed in the 1990s to work as an integrated and distributed mechanism for several types of applications in the industrial field. Among its chief features are high controller capacity and native network redundancy (based on Masterbus 300 protocol), which make up a DCS (Distributed Control System).

AC450 controller

The system has engineering (Advant Engineering) and operation (Advant Station) stations on Unix or Windows NT platforms. Distributed I/Os can be collected via AF100 bus.

Example of architecture – ABB Advant

Benefits for migrating to Elipse/Prosys solution

- Technological update of the IT infrastructure (Operation Servers and Stations), which maintain field networks and controllers, thus reducing financial costs when changing systems.

- Allows virtualization, according to each company’s IT policies.

- Parallel operation takes place during the update process: no production downtime.

- Unlimited connectivity to other systems and protocols, such as OPC.

- Local technical support with total command of the solution.

For further information, call +55 11 3061-2828 or write to v-automacao@elipse.com.br.